Producer handbook

The Quality Management Manual (short: QMM) is a company-internal compilation. Various system requirements are summarized in the QMM.

Legal and additional requirements can be documented here.

The Quality Management Manual (short: QMM) is a company-internal compilation. Various system requirements are summarized in the QMM.

Legal and additional requirements can be documented here.

At the Fruit Growing Research Station Jork (OVA) of the Chamber of Agriculture of Lower Saxony, the fruit cultivation research is conducted. The research refers to varieties, documents, planting systems, crop protection, plant nutrition, irrigation and drainage, fruit quality, equipment, application engineering and business administration.

The results of the Fruit Growing Research Station flows directly into the range of service of the Fruit-Growing Research Group of the Altes Land e.V .(OVR). It includes all Elbe-Obst members.

The Research Group takes over, first of all, the individual fruit-structural discussion based on the individual talk with the producer who is supplemented with group discussions e.g. speech evenings, specialized lectures and further training courses.

In addition, the Trial ring is the editor of the leading establishment of operating log in which the „Guidelines for the Integrated fruit growing on the Lower Elbe“ receives an annual dynamic adaptation.

The Fruit Growing Research Station Jork (OVA), the Fruit-Growing Research Group of the Altes Land e.V (OVR), the ecological fruit-growing group of North Germany (ÖON) and the water protection area consulting the Chamber of Agriculture Hamburg together form the fruit-growing experiment

and Counselling.

In addition to internal quality controls, Elbe-Obst also carries out various external quality controls. In addition to the Lower Saxony Chamber of Agriculture, there are also inspections to determine whether the guidelines of the Controlled Integrated Production are met. In addition, there are official controls and export controls.

The Chamber of Agriculture of Lower Saxony (LWK) conducts independent in-process quality checks and verifies the correctness of the sorting, processing, packaging and labeling; to avoid complaints and to have a basis for settlement with the producer.

There are daily external auditors of the Chamber of Agriculture at the sorting stations of Elbe-Obst and the production establishments in operation, so that an inspector is at least every second day, present at a Elbe-Obst sorting station. Besides, the examiners are available at any time for inquiries. Each batch checked is recorded manually on a quality decree.

According to the guidelines for the Controlled Integrated Pome and Stone Fruit growing of the Niederelbe, the Chamber of Agriculture of Lower Saxony (LWK) inspects the operations of the producer. The inspections include: Operational logs, operating equipment and orchards. Each year all the orchard registers of all the integrated-growing producers are inspected. Every year in addition – besides the controls of the quality system – 20% of the producers’ orchards are inspected and assessed.

Compliance with the provisions on marketing standards of the EU is controlled by the Lower Saxony State Office for Consumer Protection and Food Safety (LAVES) to ensure that the quality produced is retained until delivery to the consumer. The control starts with the preparation and loading of the producers shipping stage. It continues on the subsequent stages, both the wholesale and the retail trade.

The district of Stade (Office of Food Control) and the district of Cuxhaven (Veterinary) examine in the context of official food control, fruit samples for compliance with the Food, Commodities and Feed Code (LFGB) with the implementing regulations. The offices acts on suspicion and regularly through random checks, fruit tests to analyses if there are any remains. This is done at the State Food Monitoring office in Oldenburg.

The Chamber of Agriculture of Lower Saxony (LWK) performs the official control of exportable goods. It l assesses the adequacy of sorting, processing, packaging and labeling. The testing applications are made regularly by random sampling, to order, and in case of suspicion.

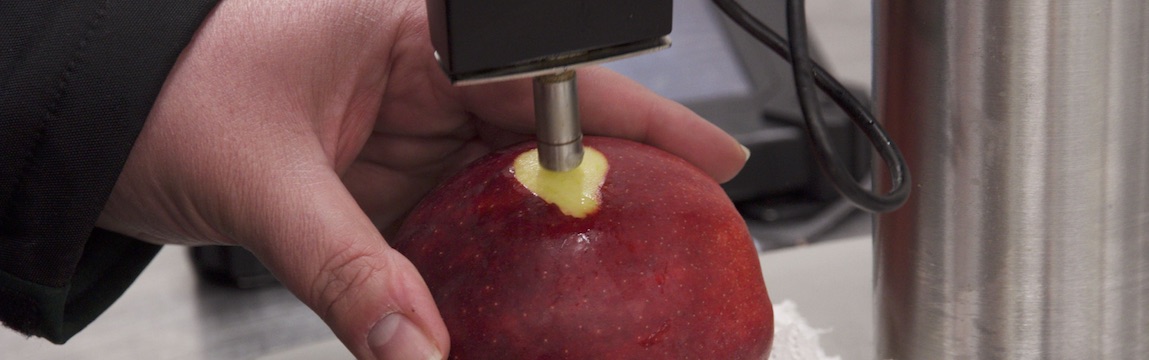

Elbe-Obst carries out quality controls along the entire production chain. In addition to incoming goods, outgoing goods are also inspected and recorded. Traceability is guaranteed for all Elbe-Obst products. In addition, residue analyses are carried out.

The aim of the inspection is the classification of the product quality for the sale at the receiving dock in sorting station of the Elbe-Obst. In accordance with legal standards and customized specifications, the goods are assessed and classified in advance and the result recorded.

The aim of the outgoing inspection is the classification and control of product quality during loading and delivery. For this purpose, the goods are assessed and documented in accordance with the regulations on quality standards for fruit and vegetables of the EU.

The internal traceability system ensures the determination of the producer of the delivered goods during the preparation and after delivery to the customer. These are documented in the compilation of the goods to a customer on the loading papers which producers are involved in each item. Therefore a direct association with the IT document entry is possible on the shipping documents starting with the delivery positions of producers to delivering positions of customers. This approach allows the traceability of a batch from food retailing back to the participating producers.

According to the guidelines of the QS residue monitoring system both on the producer businesses as well as the sorting stations of the Elbe-Obst Erzeugerorganisation r.V. samples are drawn. This task is ensured by qualified personnel. On behalf of the Elbe-Obst Erzeugerorganisation r.V. labs that are accredited and approved by the QS GmbH examine fruit samples with regard to the usage of plant protection products.

Sie müssen den Inhalt von reCAPTCHA laden, um das Formular abzuschicken. Bitte beachten Sie, dass dabei Daten mit Drittanbietern ausgetauscht werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Turnstile. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen